Description: This flute is made from acid-stained boxwood with silver keys, and ivory rings. Its head is fully lined in brass with a brass tuning slide. The outer part of the tuning slide is covered with a thin layer of boxwood with graduated markings. It has 8-keys – C, Bb, G#, long and short F, Eb, and C# and C foot keys. The keys have leather-covered pads held in place by tiny brass screws and sit on flat silver disks that mount via a square hole on a square peg. The key slots are lined in brass. The end cap has internal threads that engage with a threaded cork holder (turned from ivory), and can be twisted to fine-tune the stopper position. A finial of ivory protrudes through the end cap to give a visual indication of the stopper position.

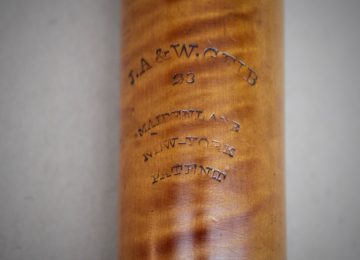

Makers marks: The head is marked “J. A. & W GEIB / 23/ MAIDEN LANE / NEW YORK / PATENT”. The barrel is marked “J. A. & W GEIB / 23/ MAIDEN LANE / NEW YORK / PATENT”. The left hand section of the body is marked “J. A. & W. GEIB”. The right hand body section is marked “J. A. & W. GEIB”. The foot is marked “J. A. & W. GEIB”.

History: J. A. & W. Geib was a partnership between John Geib junior (born in London 1780, died in New York 1821), his twin brother Adam Geib (born London 1793, died 1849) and William Geib (born London 1793, died Philadelphia 1860). They were the sons, partners and successors of the organ builder John Geib senior. The business was listed as J. A. & W. Geib in 1818. By 1821 it was listed as A & W. Geib (after John’s death). So this flute dates between 1818 and 1821. It is likely that the Geibs were dealers of flutes rather than makers.

Tuning: This flute plays best in tune at A=430 hz with a tuning slide extension of around 18mm at 70 degrees F, but has flat foot notes (Eb, D, C# and C).

Specifications: C# – D# 263 mm. L2 tone hole 7 mm. R2 tone hole 6.9 mm.

Condition: This flute is now in good playing condition. My restoration work on this flute included repairing a crack in the back of the head, a thorough cleaning and polishing of every part, re-padding all keys, ensuring proper action, and thread-wrapping all tenons.